Available equipment

The Energy Materials lab has available several 3D printing technologies, techniques for developing new materials such as thin films deposition, nanoparticles synthesis and application in many types of materials for functionalization and hence, multiple characterization techniques - ranging from structural/morphology techniques to optical and thermoelectric characterization

Equipment list

Substrates cleaning

Films deposition and nanoparticles synthesis techniques

Morphology characterisation

Composition characterisation

Optical properties characterisation

Electrical and thermoelectric properties characterisation

Annealing furnaces

- Compact atmosphere controlled furnace (up to 1000 °C)

- High-temperature furnace (up to 1800 °C)

- Muffle furnace (up to 1100 °C)

3D printing

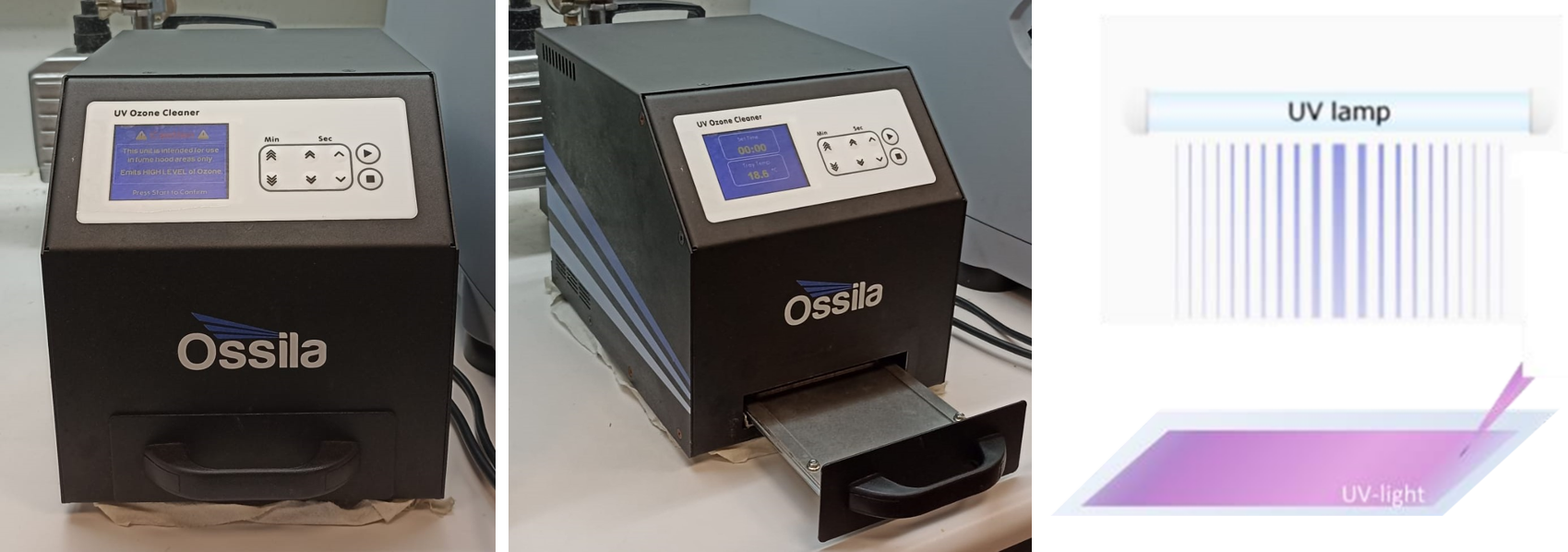

UV Ozone Cleaner

Equipement details

- Name: UV Ozone Cleaner

- Brand model: Ossila UV - Ozone Cleaner

- Brand website: https://www.ossila.com/en-eu/products/uv-ozone-cleaner

- Description: UV Ozone Cleaner removes contamination from the surface of substrates, providing ultraclean surfaces within minutes.

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: Lab. 209

Films deposition and nanoparticles synthesis techniques

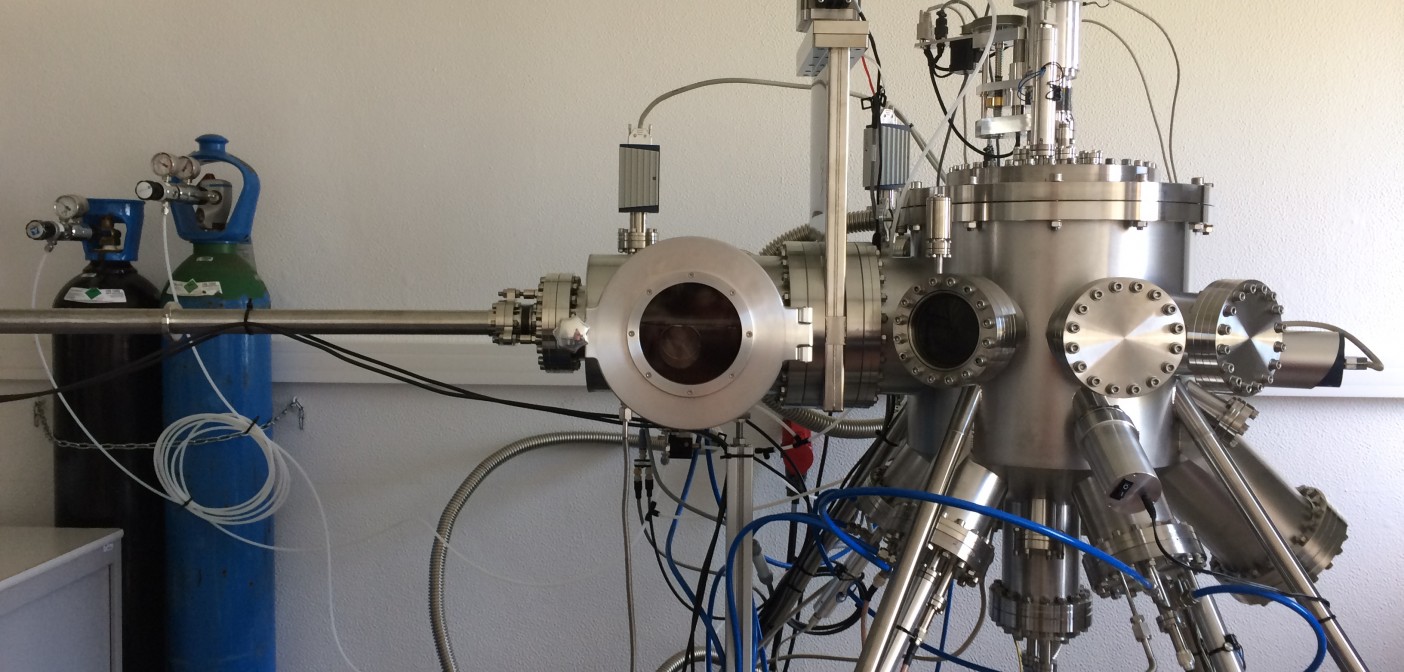

Sputtering machine

Equipement details

- Name: RF Sputtering

- Brand model: Personalised Mantis system

- Brand website: www.mantisdeposition.com

- Description:Sputtering system to create thin films of materials used in the production of thermoelectric devices and transparent contacts

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: 213

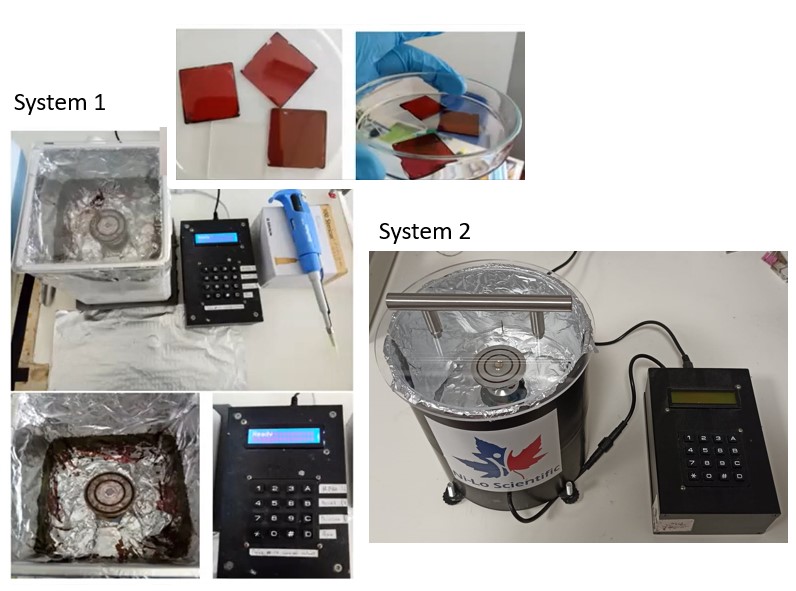

Resistive Thermal Evaporation

System 1

Equipement details

- Name:Homemade resistive thermal evaporation system

- Description:Physical Vapor Deposition (PVD) of thin films, metallic and oxides by joule heating of a resistive boat

- Departement: DCM - Departamento de Ciências dos Materiais

- Room:Lab. Películas Finas

System 2

Equipement details

- Name: Multiple source evaporation system (sputtering, thermal boat and e-beam evaporator sources)

- Brand model: Korvus Technology - HEX series

- Brand website: https://korvustech.com/wp-content/uploads/2022/11/Korvus-6pp-Brochure-Master-17.6.22.pdf

- Description: HEX modular coating system for thin film deposition. The HEX deposition system is highly flexible and versatile, offering users the ability to re-configure and upgrade their HEX. In our equipment, we have the following deposition sources available: magnetron sputtering, thermal boat and e-beam evaporator source.

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: Lab. 209

Spin Coating

Equipement details

- Name: Spin-coater

- Brand model: Ni-Lo 4 Vacuum Holder Spin-Coater

- Brand website: http://niloscientificuk.weebly.com/spin-coaters.html

- Description: Systems 1 and 2 are identical, but the later has the capability of vacuum holding the samoples (instead of using double sided tape). Both are well suited for thin-film depositions on flat substrates and deposition parameters are: speed, acceleration and duration. Which can be programmed in the controller for a single or multiple steps.

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: Lab. 209

Spray

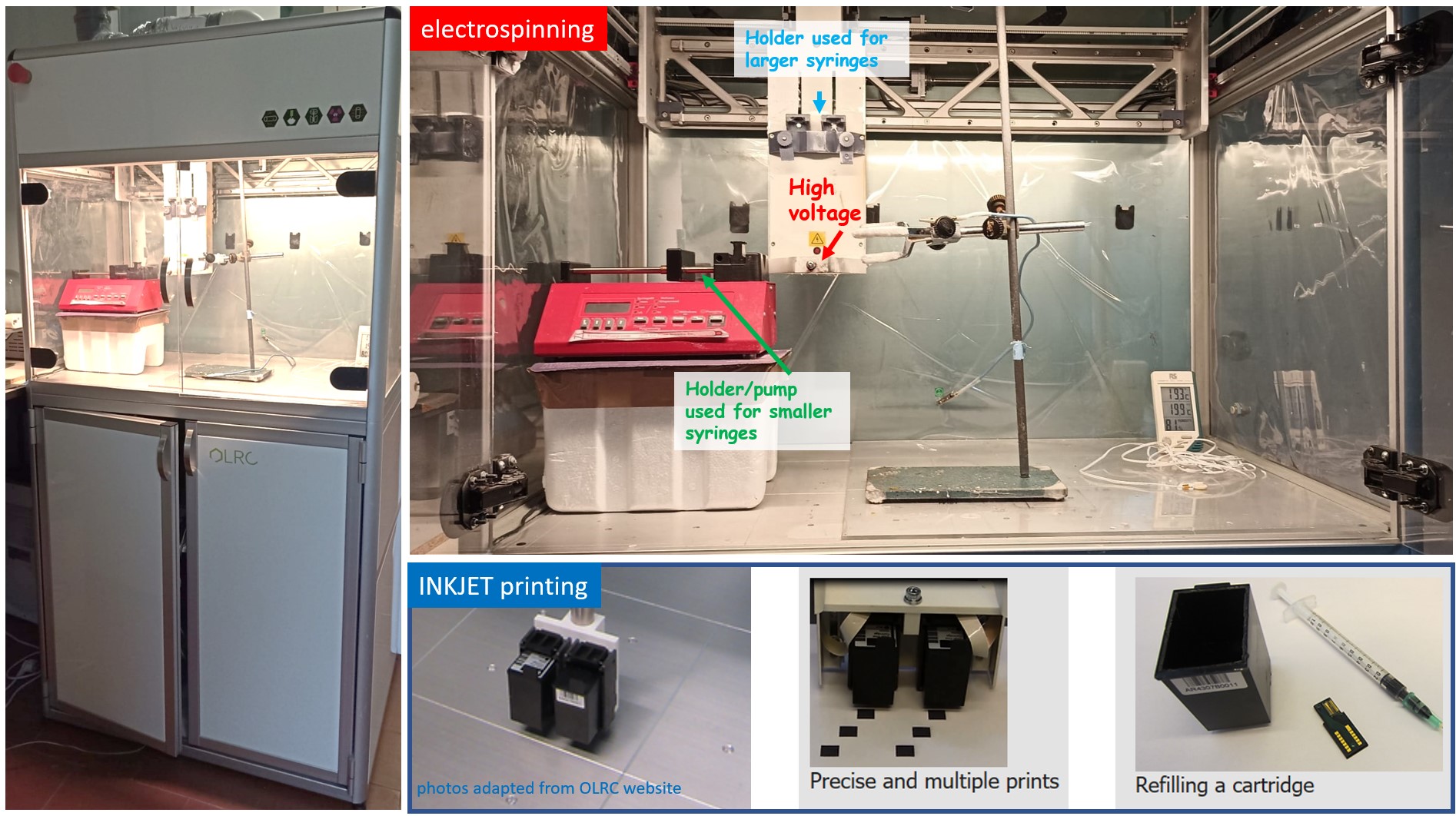

Multicoater

Equipement details

- Name: MultiCoater

- Brand model: LRC - MultiCoater

- Brand website: https://fredfy2002.wixsite.com/labratcustoms/modules

- Description: Multi-coater is equipped with an electrospinning module and an Inkjet nozzle. This allows for electrospinning and electrospray depositions, with the electrospinning module, and for inkjet printing with the inkjet nozzle. Since for proof of concept applications small quantitates of solutions are needed a standard syringe pump is used in conjunction with the HV module that is provided in the LRC electrospinning accessory. The target is placed at an adjustable distance.

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: Lab. 213

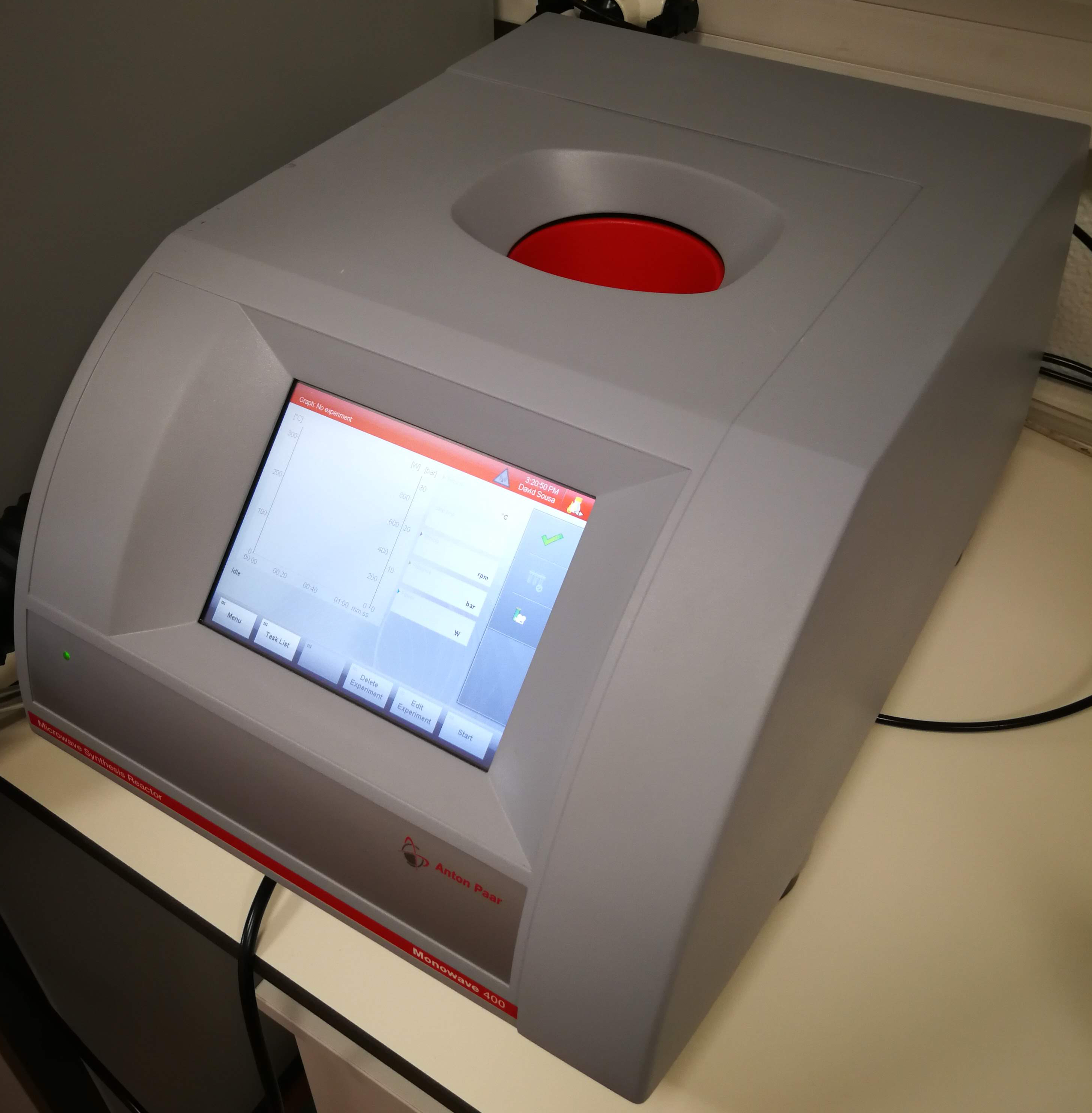

Microwave

Equipement details

- Name: Microwave Synthesis Reactor

- Brand model: Monowave 400

- Brand website: https://www.anton-paar.com/corp-en/products/details/microwave-synthesis-monowave-400200/

- Description: Synthesis of nanoparticles

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: 213

Morphology characterization

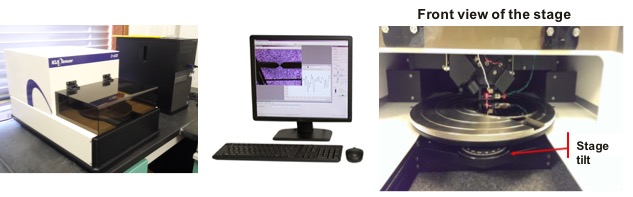

Profilometer

Equipement details

- Name: AlphaStep D-600 Stylus Profiler

- Brand model: KLA Tencor

- Brand website: https://www.kla-tencor.com/Surface-Profiling/alpha-step-d-600.html

- Description: Measure of film thickness and 3D mapping of solid samples

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: 213

Atomic force microscopy

Equipement details

- Name: Atomic force microscope

- Brand model: ALPHA RAS 300

- Brand website: https://www.witec.de/products/afm-microscopes/alpha300-a/?gclid=EAIaIQobChMInp7jpq6C5QIV1vhRCh2DzgpgEAAYASAAEgJtivD_BwE

- Description:This atomic force microcope is designed for surface characterization on the nanometer scale (with lateral resolution down 1 nm and depth resolution < 0.3 nm). Two main operation modes are available: Contact Mode / lateral force and AC-mode / Phase imaging. WITec software for instrument and measurement control, also allows data evaluation and processing. For exemple, it allows determing the surface roughness.

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: 213

Composition characterization

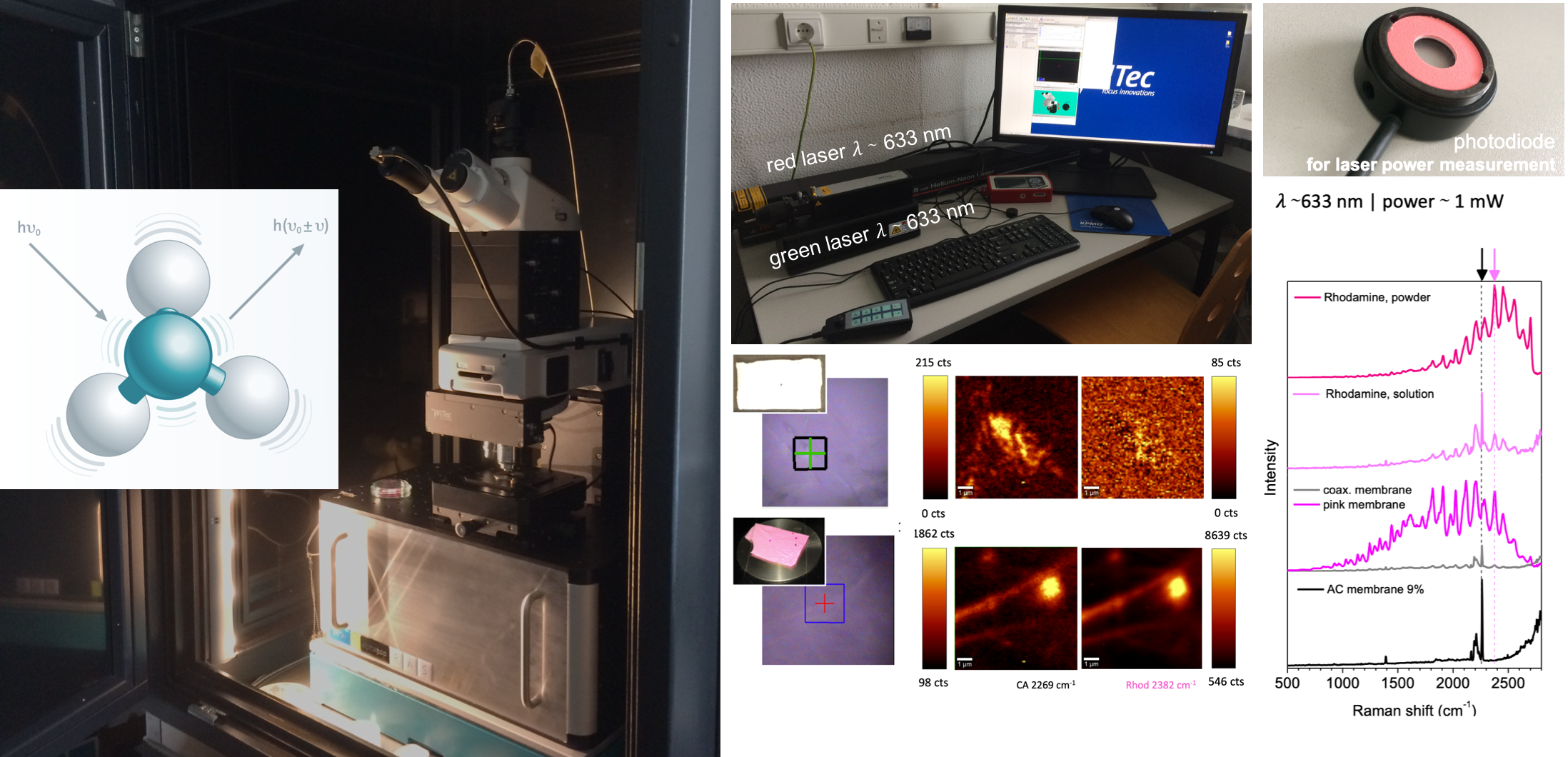

Raman microscopy

Equipement details

- Name: Confocal Raman microscope

- Brand model: ALPHA RAS 300

- Brand website: https://www.witec.de/assets/Literature/Files/WITec-alpha300-Brochure.pdf

- Description: A Raman spectrum provides sample information about quantitaty of a specific compound (peak intensity), identification of stress and strain states (peak shift), crystal symmetry and orientation (polarization state), etc. The microscope is suitable for single point acquisition spectra and 2D imaging and also for depth profiling due to its high confocality. Raman imaging allows visualizing the distribution of the sample’s compounds. The minimum lateral spatial resolution is ~200 nm. Two exciting wavelengths for the incident light are available at the Energy Materials Lab: 533 nm and 633 nm.

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: 213

Optical properties characterization

UV-VIS-NIR Spectrophotometer

Equipement details

- Name: UV-VIS-NIR Spectrophotometer

- Brand model: JASCO V-770 Spectrophotometer

- Brand website: https://jascoinc.com/products/spectroscopy/uv-visible-nir-spectrophotometers/models/v-770-uv-visible-nir-spectrophotometer/

- Description: Measures Transmittance, Absorbance and Reflectance

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: 213

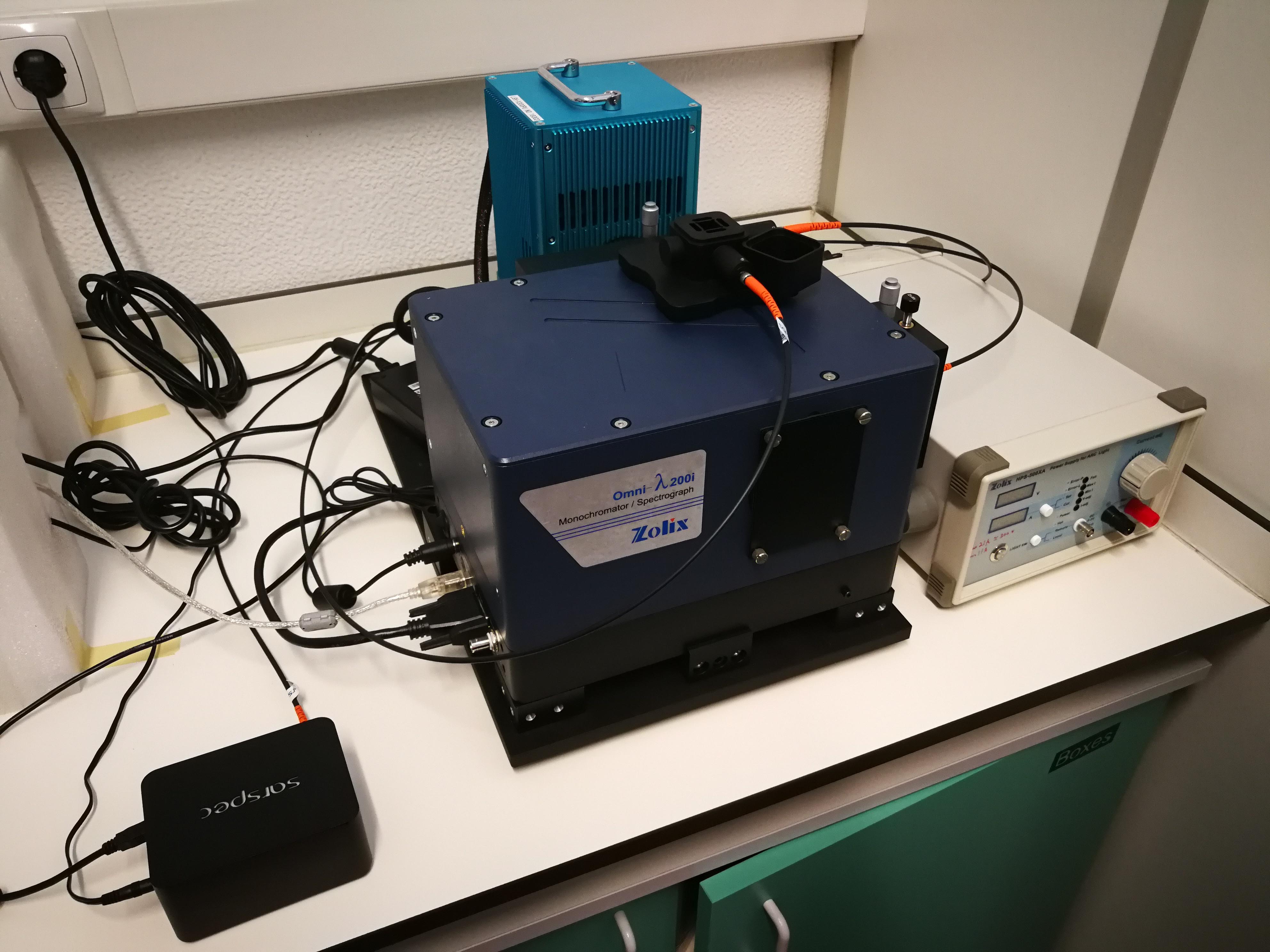

Flurimeter

Equipement details

- Name: Flurimeter

- Brand model: Spec Sense+ Spectrometer (SP-SENSE-FL)

- Brand website: Sarspec Sensor http://sarspec.com/docs/Spectrometers/Spectrometer_Manual_Sarspec.pdf/14 + Monochromator Zolix omni-λ200i http://www.zolix.com.cn/en/prodcon_370_376_741.html

- Description: Measuring emission and excitation spectra of liquid and thin film samples

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: 213

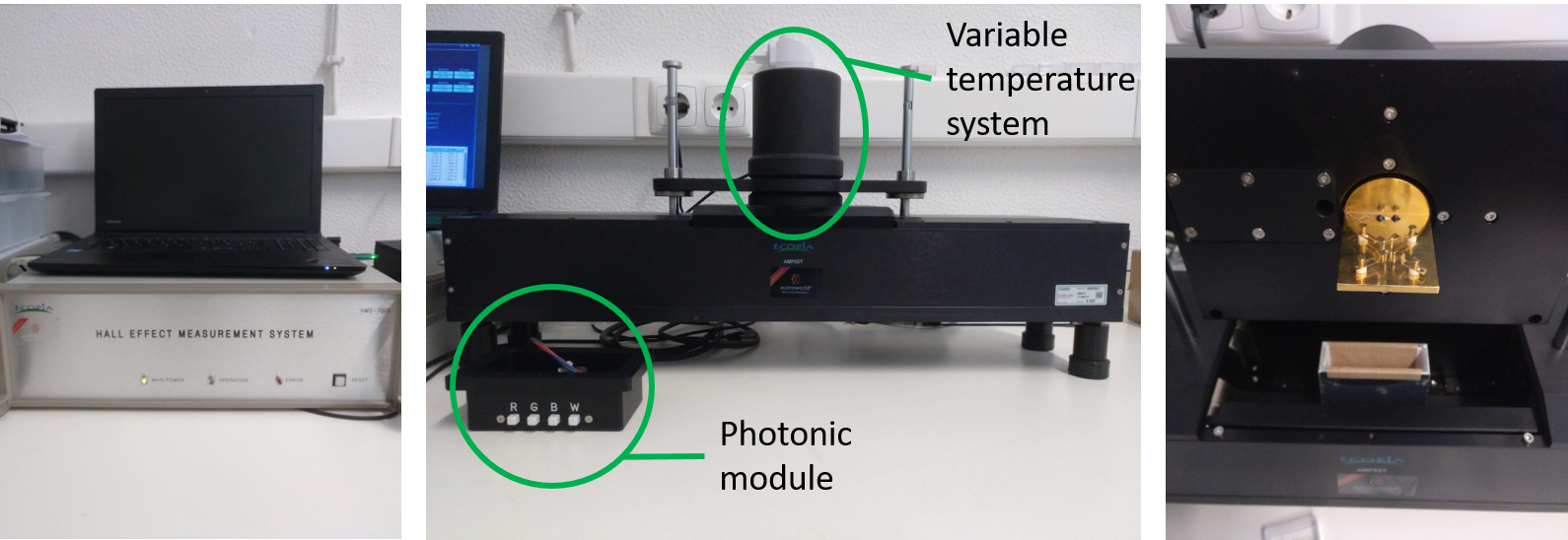

Electrical and thermoelectric properties characterisation

Photonic Hall Effect

Equipement details

- Name: Ecopia HMS-7000 with AMP55T (low temperature system)

- Brand model: Ecopia

- Brand website: http://www.ecopia21.co.kr/bbs/board.php?bo_table=eng_product&wr_id=20&sca=New+item

- Description:Measures of resistivity, carrier concentration, mobility, hall coefficient, N/P type decision at temperatures ranging from 80 – 350K

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: 213

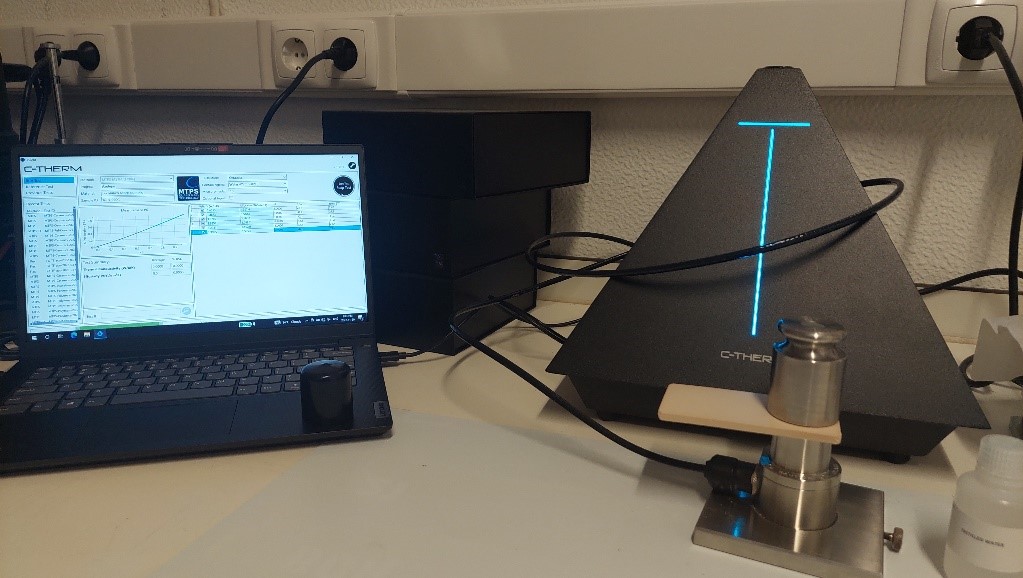

Thermal conductivity setup

Equipement details

- Name: Trident Thermal Conductivity

- Brand model: C-Therm

- Brand website: https://korvustech.com/wp-content/uploads/2022/11/Korvus-6pp-Brochure-Master-17.6.22.pdf

- Description: The trident system is a fast and accurate instrument. Allows for thermal conductivity testing of a wide range of solids, thin films, powders and pastes through the different sensors available.

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: Lab. 213

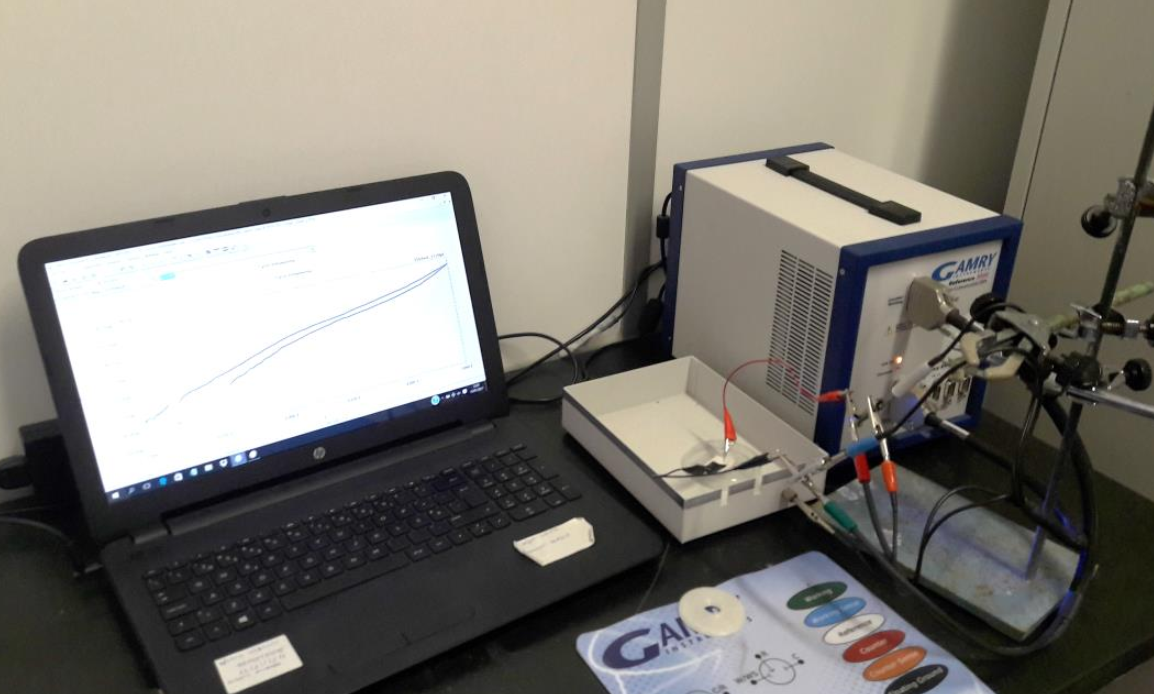

Potentiostat

Equipement details

- Name: Potentiostat/Galvanostat/ZRA

- Brand model: Reference 3000 AE with Auxiliary Electrometer

- Brand website: https://www.gamry.com/potentiostats/reference-3000-auxiliary-electrometer/

- Description: Performs electrochemical measurements and data analysis with the "Gamry Echem Analyst" software

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: 213

Annealing furnaces

Compact atmosphere controlled furnace (up to 1000 °C)

Equipement details

- Name: Atmosphere controlled furnace

- Brand model: OTF – 1200X – 4-RTP

- Brand website: https://www.mtixtl.com/CompactRTPFurnace4QuartzDigitalVacuumGauge-OTF-1200X-4-RTP.aspx

- Description: OTF-1200X-RTP-4 is a compact rapid thermal processing tube furnace with a 4" I.D. processing quartz tube and vacuum flanges. It is designed for annealing semiconductor wafers or solar cells with diameters up to 3". OTF-1200X-4-RTP is heated by 8 units of 1KW halogen light with a max. the heating rate of 50ºC/second. 30 segment precision temperature controller with +/-1ºC accuracy is built into the furnace to allow for heating, dwelling, and cooling at various steps. RS485 port and control software are included to make monitoring the temperature profile via PC while simultaneously running furnace possible. Max. temperatures: 1100 °C for 10 minutes; 1000 °C for 20 min.; 800 °C for 120 min. and 600 °C for continuos.

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: Lab. Lab. Películas Finas

High-temperature furnace (up to 1800 °C)

Equipement details

- Name: High-temperature furnace

- Brand model: Nabertherm LH 08/18 Furnace

- Brand website

- Description: This furnace is simple to operate and is well suited to sinter technical ceramic, e.g. zirconium oxide dental bridges. This high-temperature furnace reach a max. furnace chamber temperature of 1800 °C.

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: Lab. Películas Finas

Muffle Furnace (up to 1100 °C)

Equipement details

- Name: Muffle furnace

- Brand model: Nabertherm L 3/11 (B-180 controller)

- Brand website

- Description: Muffle furnace is ideally suited for heat treatment in large number of processes in the field of material research. Optimal temperature uniformity of +/- 5K with closed fresh air inlet in empty workspace.

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: Lab. 213

3D printers

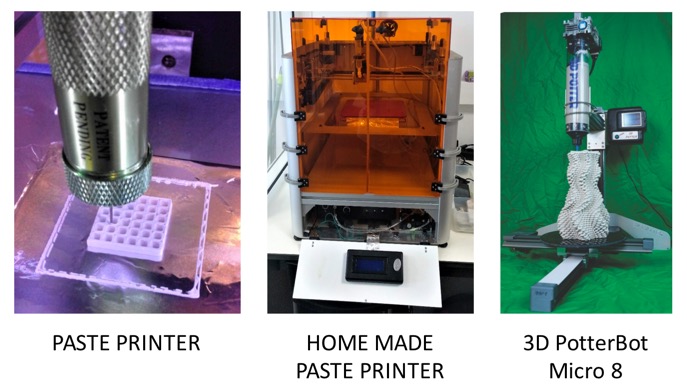

Paste printers

Equipements details

|

Model: |

Paste printer | Home made paste printer | 3D PlotterBot Micro 8 |

| Brand website: | - | - | www.deltabots.com |

| Description: | Printing of 3D objects by mechanical extrusion of pastes, for example ceramic pastes. This equipment can also work with a filament printer, has another adapter for this feature. | Printing 3D objects by extruding compressed air from pastes, for example hydrogels. This equipment has a laser for crosslinking the paste during printing. In addition to 3D printing, this equipment can also be used to make spray deposition. | 3D Potter is an entry-level 3D ceramic printer. Can print clay in large quantities (up to 1000mL) |

| Departement: | DCM - Departamento de Ciência dos Materiais | DCM - Departamento de Ciência dos Materiais | DCM - Departamento de Ciência dos Materiais |

| Room: | 209 | 209 | 209 |

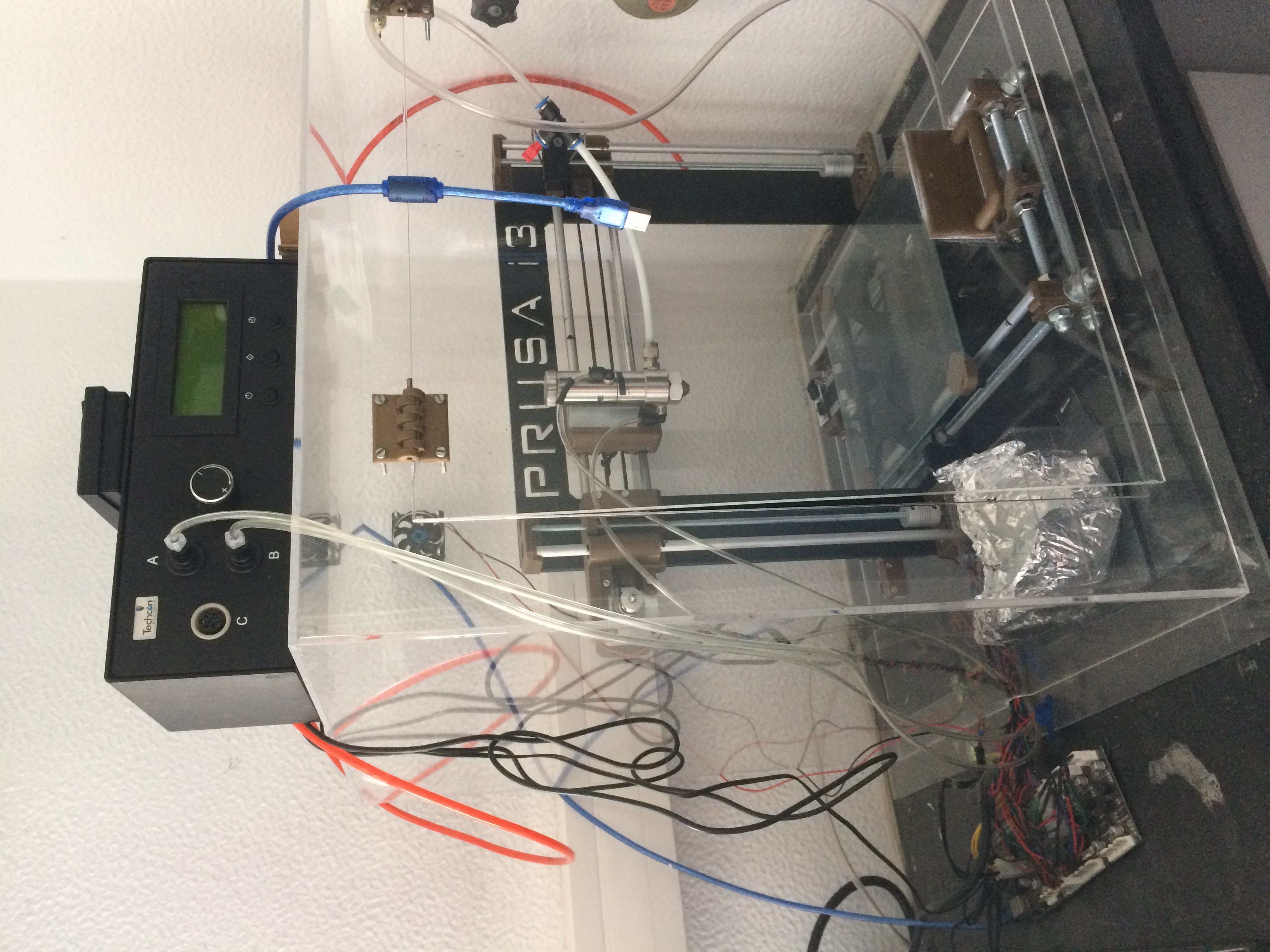

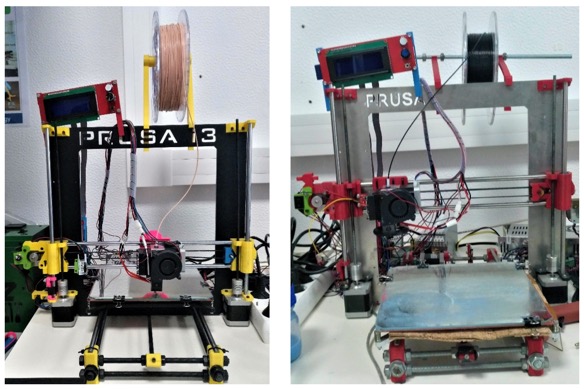

Filament printers

Equipement details

- Name: Prusa

- Brand model: Prusa i3

- Brand website: www.prusa3d.com

- Description: Make three dimensional solid objects from extrusion of filament. Used many types of filament, for example PLA and ABS (are the more usually).

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: 209

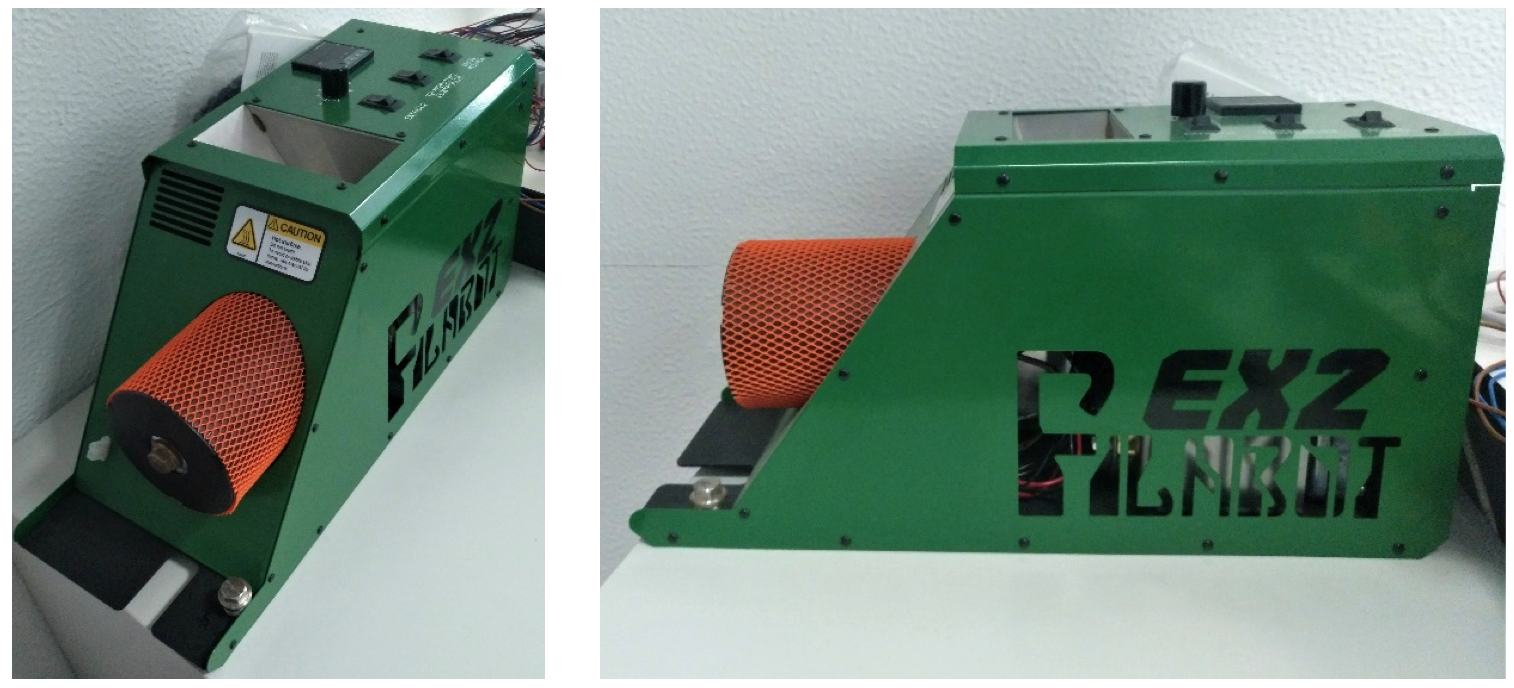

Extruder of filament

Equipement details

- Name: Filabot

- Brand model: Filabot EX2 filament extruder

- Brand website: www.filabot.com

- Description: The Filabot EX2 system is a mid level extrusion system. The goal this equipement is the recycling is that failed prints don't end up in the trash.

- Departement: DCM - Departamento de Ciências dos Materiais

- Room: 209